Intergrana Grows: Expansion of the Cheese Storage Warehouse Completed

At Intergrana S.r.l., quality is not created solely in the finished product, but in everything that surrounds it: organization, control, and attention to detail. Guided by this vision, we have completed a major expansion of our cheese storage warehouse—a strategic project designed to support the company’s growth and further enhance the efficiency of the service we offer our customers.

Storage capacity doubled to meet an evolving market

The new warehouse doubles our storage capacity, allowing us to manage higher volumes in an orderly, flexible, and safe manner.

This expansion translates into greater product availability, faster handling times, and even more precise logistics planning, even during peak demand periods.

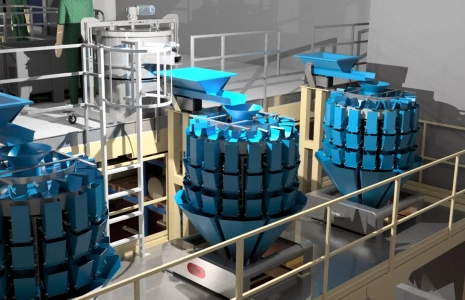

Over 1,000 m² of automated racking systems

At the heart of the project are more than 1,000 m² of automated racking systems, designed to efficiently store and handle the various types of cheese.

Thanks to automation, we are able to:

- improve order and traceability of warehouse locations

- reduce errors and unnecessary handling

- ensure faster and more controlled batch management

A real step forward that strengthens our ability to operate with continuity, precision, and reliability.

Every cheese stored under its ideal conditions

Each cheese has specific requirements: temperature and humidity are key factors in preserving structure, sensory characteristics, and quality over time.

The new storage system has been designed to ensure stable and consistent storage conditions, fully respecting the needs of each product type.

Optimized logistics flows for greater efficiency

The expansion goes beyond increasing available space. We have redesigned the entire internal logistics system to make workflows more streamlined and faster, reducing unnecessary steps and improving handling management.

The result is greater operational efficiency, with quicker preparation and transfer times, without ever compromising the level of control.

Enhanced food safety with new automated sanitation zones

Among the most significant improvements is the introduction of new automated goods sanitation zones, strategically positioned before entry into production areas.

This additional step allows us to:

- strengthen protection of products and environments

- reduce the risk of cross-contamination

- increase the level of control during transitions between warehouse and production

A tangible improvement that aligns with our daily commitment to food safety and compliance with the highest quality standards.

Looking to the future

This expansion represents a major investment in continuity, reliability, and quality: increased capacity, greater automation, more efficient flows, and further reinforcement of hygiene measures.

In other words, a facility designed to grow without compromising what truly matters to us: product care, process control, and customer focus.

Intergrana continues to evolve every day, to offer a service that is increasingly efficient, safe, and fully aligned with market expectations.

Related Articles