Digitizing Industrial Plants: Turning Complexity into Competitive Advantage

In today’s modern food production landscape, the complexity of industrial plants has grown exponentially in recent years. Increasingly sophisticated production lines, strict hygiene regulations, and the integration of Industry 4.0 technologies have made an innovative approach to plant design and management essential.

Faced with ever more intricate layouts and constantly evolving production demands, clear and understandable communication — even with non-technical stakeholders such as managers, investors, and procurement officers — has become a critical success factor. The ability to visualize, simulate, and optimize plants even before they are physically built is now a decisive competitive advantage.

Always attentive to technological innovation and operational efficiency, Intergrana has taken a strategic step forward in the digitization of its design processes. The company has developed a concrete, cutting-edge solution to simplify technical communication and optimize the design of production plants in the dairy sector.

Overcoming the Limits of Traditional Design

Classic 2D drawings made with traditional CAD software, while still valuable for technical documentation, are often no longer sufficient to convey the true complexity and potential of a modern production plant. A two-dimensional drawing, no matter how accurate, leaves room for interpretation and requires specialized skills to be fully understood.

When working with commercial partners, machinery suppliers, international clients, or investors who lack a technical background, the risk of misunderstandings, project delays, or decisions based on incomplete information is ever-present. These issues inevitably lead to additional costs, extended timelines, and potential installation errors.

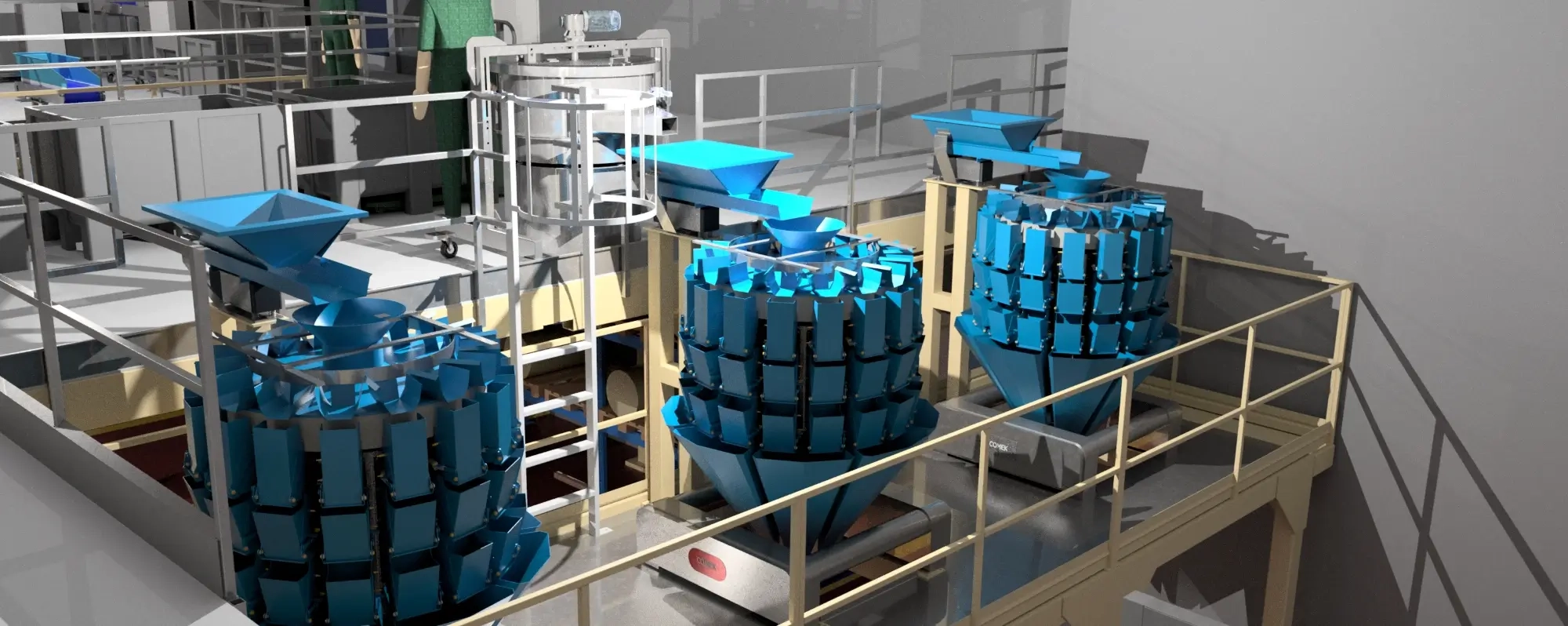

That’s why we are integrating advanced 3D modeling tools and BIM (Building Information Modeling) technologies — offering realistic, immersive, and dynamic views of a plant before it is even built. This approach drastically reduces the margin for error, facilitates dialogue among all project stakeholders, and speeds up decision-making processes.

From Idea to Digital Twin: Advanced Design with Inventor, AutoCAD, and Revit

Thanks to professional software tools from the Autodesk suite — including Inventor, AutoCAD, and Revit — our team of engineers and designers can now create complete, integrated, and highly customized layouts, both in 2D (for technical documentation) and in interactive 3D models (for presentations and simulations).

These tools allow us to:

- Intelligently visualize and optimize space, maximizing the efficiency of internal logistics and minimizing material movement times across production zones.

- Simulate future integrations or modifications to existing facilities, evaluating the impact of new production lines, expansions, or conversions in advance — without interrupting operations.

- Design clear, well-integrated safety paths in compliance with regulations, ensuring the well-being and protection of operators, maintenance staff, and visitors under any operational condition.

All of this leads to the creation of a true digital twin of the plant: a dynamic digital replica, constantly updated and synchronized with the real facility. This enables predictive maintenance, long-term strategic planning, and more efficient control of the entire production site.

More Efficiency, More Safety, More Economic Value

Our approach is based on a key concept: turning complexity into a measurable competitive advantage. Every industrial plant in the food sector has unique characteristics, specific constraints, and particular production goals. That’s why customization is at the heart of our digital design philosophy.

The concrete benefits of this technological evolution translate into:

- Increased productivity – up to 20–30% more – thanks to smoother space management, optimized workflows, and reduced downtime between production stages.

- Optimized environments, with functional and ergonomic layouts that can easily adapt to market demand changes or the introduction of new products.

- Guaranteed safety, with pedestrian paths, escape routes, and emergency areas mapped and integrated into the design from the earliest stages, fully compliant with HACCP and workplace safety regulations.

- Reduced construction costs, by identifying and solving design issues virtually, before they become costly on-site errors.

- Shorter implementation times, with an average 15–25% reduction compared to traditional methods, thanks to better coordination among project stakeholders.

- Greater environmental sustainability, through optimized energy consumption, waste reduction, and improved resource management.

The Future Starts with a Clear, Shared Vision

We believe that innovation means simplifying what is complex and making accessible what once seemed understandable only to a few specialists. Plant digitization is not a technological whim, but a strategic necessity for companies that want to remain competitive in an increasingly demanding global market.

Investing in advanced design tools means adopting a common language that fosters collaboration, accelerates decision-making, and drastically reduces risks associated with building new plants or upgrading existing ones.

Related Articles