How We Select Our Parmigiano Reggiano

Origin, Procedures and Certifications

In the world of the food industry, every detail matters. That’s why selecting Parmigiano Reggiano PDO for packaging is much more than a matter of taste: it’s a technical, rigorous, and structured process designed to ensure quality, safety, and performance.

At Intergrana, the selection of Parmigiano Reggiano is not just a matter of experience: it’s a certified procedure, marked by precise steps and objective tools.

Our goal? To provide food industry clients with a product that meets the highest quality standards—both technically and functionally.

Let’s take a closer look at how our approval process works.

Step 1 – Document Review and Analytical Comparison

Our selection process always begins with a thorough document review. Suppliers of Parmigiano Reggiano PDO are required to provide updated laboratory analyses of the product, which we compare against our internal quality standards.

This comparison goes beyond routine checks—we evaluate specific parameters such as moisture, protein content, microbial load, and fat composition. These are essential to determine the cheese’s workability in industrial environments.

Only cheeses that fully meet our requirements move on to the next stage.

Step 2 – Sample Testing at Our Laboratory

Once the documentation check is passed, a sample of the cheese is tested at our accredited laboratory.

Here, the Parmigiano Reggiano is examined under controlled conditions following technical protocols that allow us to assess:

- the texture and structure of the cheese interior,

- its behavior during cutting and processing,

- the product’s homogeneity and stability over time.

This step is crucial in predicting how the product will perform during subsequent portioning, grating, and packaging phases.

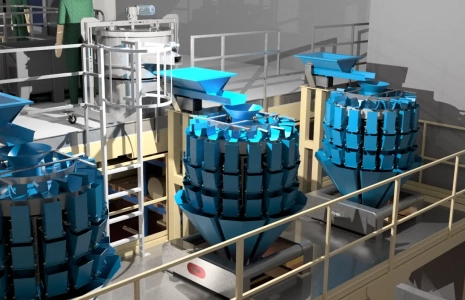

Step 3 – Processing Test at Our Production Facility

The real test, however, comes in the third phase. The selected cheese is tested directly at our production plant, simulating the actual processing cycle. Here we evaluate:

- cutting yield and final product definition,

- mechanical resistance during portioning,

- consistency with packaging and shelf-life expectations.

Only if the Parmigiano Reggiano PDO successfully meets all criteria in this stage can it be considered suitable for production launch.

Small Batch Testing: The Final Trial Before Full-Scale Production

Even cheeses that pass the entire process with flying colors do not immediately enter full-scale production. At Intergrana, we implement a small batch testing phase, which allows us to:

- monitor product stability over time,

- fine-tune production line settings,

- ensure consistent quality in large-scale supply.

This additional step is further confirmation of our commitment to delivering not only excellent, but also reliable and high-performing Parmigiano Reggiano PDO for the food industry.

Why This Process Makes the Difference

Our selection method is more than an internal procedure—it’s a true differentiating factor that allows us to offer:

- High-yield cheeses designed to ensure efficiency in our clients’ production processes;

- Full safety and traceability, thanks to documentation verification and certified PDO origin;

- Customization and control, tailoring each selection to the specific needs of our partners.

Choose Intergrana:

Where tradition and innovation come together to shape your ideal product.

Related Articles