Sustainable food Plastic Packaging: The Impact of the Thickness

Sustainable food plastic packaging represents a crucial challenge in the food industry. The Research & Development department of Intergrana has dedicated over two years to market research and testing to identify a plastic material that could be truly sustainable for cheese single servings. In this article, we will explore the impact of film thickness in packaging and how Intergrana’s innovation is making a difference.

The Search for a Sustainable Material

During the research phases, various hypotheses of recyclable materials were considered. The choice fell on a recyclable packaging, capable of being disposed of in plastic and subsequently treated for new use. Despite the “recyclable” claim being clearly visible on the final packaging, the currently available technology does not allow for a particularly thin material, thus limiting the real sustainability of the product.

The studies conducted took into account various aspects, including the material’s resistance, its ability to protect the product, and ease of recycling. A crucial point was finding a balance between environmental sustainability and packaging functionality. In fact, a material that is too thin might not ensure optimal preservation of the cheese, thus compromising the quality of the final product.

The Innovation of Thin Packaging

The true innovation introduced by Intergrana’s technicians was the thinning of the standard packaging. This reduction has made it possible to minimize the amount of plastic used for each kilogram of packaged cheese. Considering the options currently available on the market, this solution is the most sustainable, pending further technological advancements that allow for further reduction in the thickness of recyclable materials.

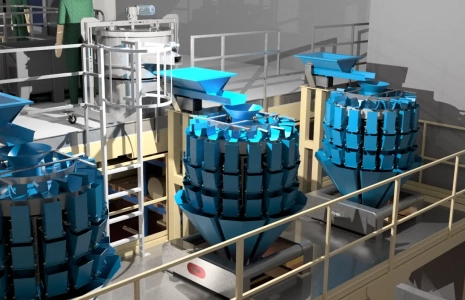

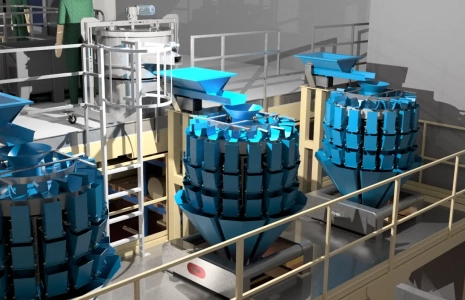

Intergrana has significantly invested in new production technologies that allow the creation of a thinner plastic film without compromising the strength and quality of the packaging. This process required numerous iterations and tests to ensure that the new packaging could withstand the same transportation and storage conditions as traditional materials.

Results and Environmental Impact

In 2024, Intergrana launched the first productions with the new thin packaging on the market. These packages have been positively received by consumers, thanks to the reduced plastic content: up to 40% less compared to traditional cheese single servings. This change is noticeable to the touch, with packaging that resembles tissue paper but retains all the necessary preservation properties for an elite product like Parmigiano Reggiano, ensuring a shelf life of up to 180 days.

The environmental impact of this innovation is significant. Reducing the thickness of the packaging not only decreases the amount of plastic used but also reduces the overall volume of waste.

Conclusions and Future Prospects

Intergrana’s commitment to research and development of sustainable plastic packaging represents an important step forward in reducing environmental impact. The reduction in film thickness is just the beginning, pending new technologies that will further improve the overall environmental impact of the materials used. Intergrana will continue to innovate, promoting increasingly ecological solutions for the packaging of its products.

Future prospects include the exploration of new mono-component materials suitable for recycling technologies available in Europe, which will reduce the environmental impact of packaging. Furthermore, collaboration with other leaders in the food sector could accelerate the development and adoption of sustainable packaging technologies globally.

Related Articles