Quality control of cheese single servings: a guarantee for the Final consumer

Intergrana’s technical department have worked long and hard to find a solution to reduce the rate of “defective” packages to below 1%. But why is this so important?

The importance of quality check in cheese single servings

Cheese single servings are included in trays of sliced carpaccio, fourth-range salads, and ready-to-eat dishes of all kinds. The selling price of the finished product ranges from €3 to €8, compared to a few cents for the packaging of the single cheese ingredient. For this reason, a packaging error that leads to mold formation in the cheese single serving risks compromising a finished product with a 50 times higher value.

The need for adequate process control

Adequate process control is essential to ensure product safety. If there are not enough controls or if they are not applied correctly, the risk of mold increases significantly. The percentage of moldy packages is perceived negatively when it exceeds 2% of total production.

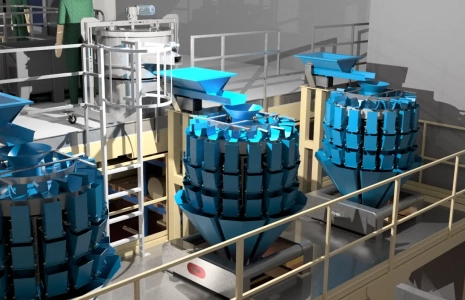

At Intergrana, we check 2,000 packages every 30 minutes using automatic sealing control machines.

Factors contributing to mold formation

Another factor that can contribute to mold formation is improper packaging procedures. It is necessary to find the right balance between:

- Plastic packaging material, better with a sealing PE layer

- Packaging speed

- Machine parameters, such as sealing temperature and contact time of the hot bars on the plastic

Intergrana’s approach to quality control

Intergrana has developed a rigorous and automated quality control system for cheese single servings. Every phase of the production process is monitored to ensure that the highest standards are consistently maintained.

Thanks to these measures, we have reduced the percentage of defective packages to less than 1%, ensuring that our finished products are always of the highest quality. Our attention to details and use of advanced technologies allow us to prevent mold formation and other defects that could compromise food safety and customer satisfaction.

Conclusions

Quality control of cheese single servings is a crucial element to ensure the safety and quality of the finished products that reach the final consumer. Thanks to Intergrana’s commitment and the implementation of advanced control systems, it is possible to maintain high standards and minimize the risk of defects. This not only protects the value of the final product but also guarantees customer trust and satisfaction.

Additionally, continuous monitoring and optimization of packaging parameters are essential to maintaining consistent quality over time. Intergrana not only invests in cutting-edge technology but also in the continuous training of its staff to ensure that each phase of the process is carried out with the utmost precision.

Our commitment to innovation and quality does not stop here. We continue to explore new technologies and methodologies to further improve our processes, continuously reducing the margin of error and increasing customer satisfaction. Consumer feedback is essential for us, and we constantly work to proactively respond to market needs.

Related Articles